Our Feature

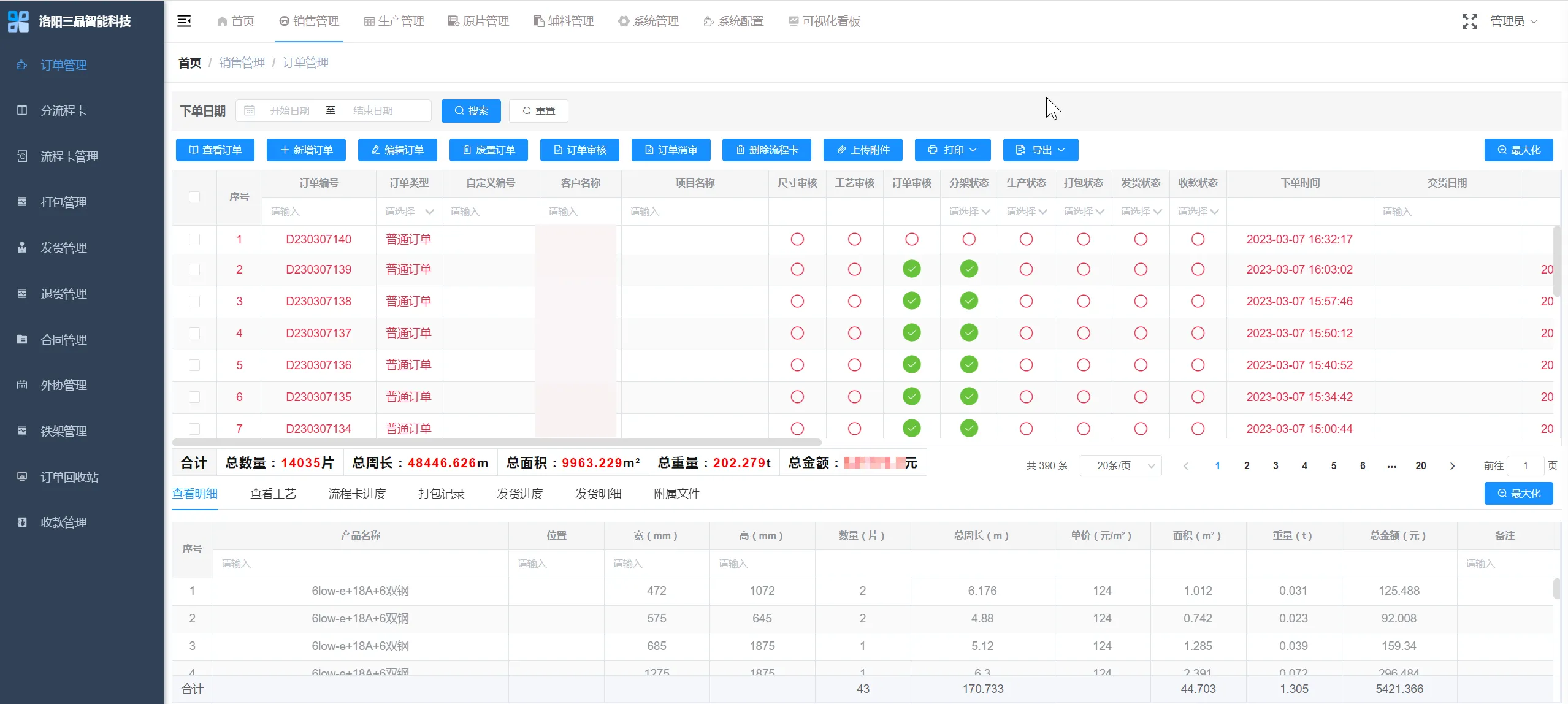

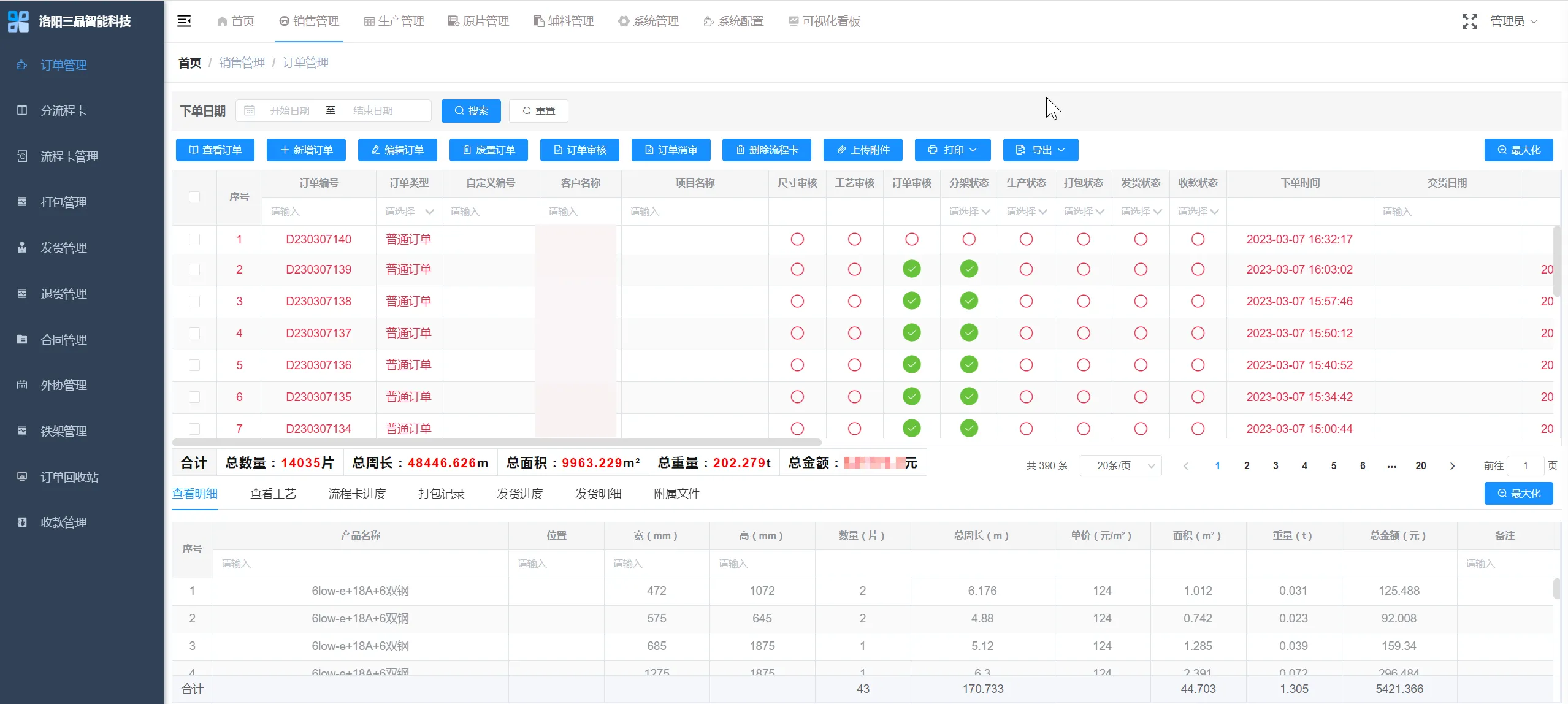

1. Sales management

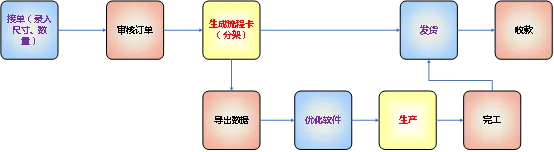

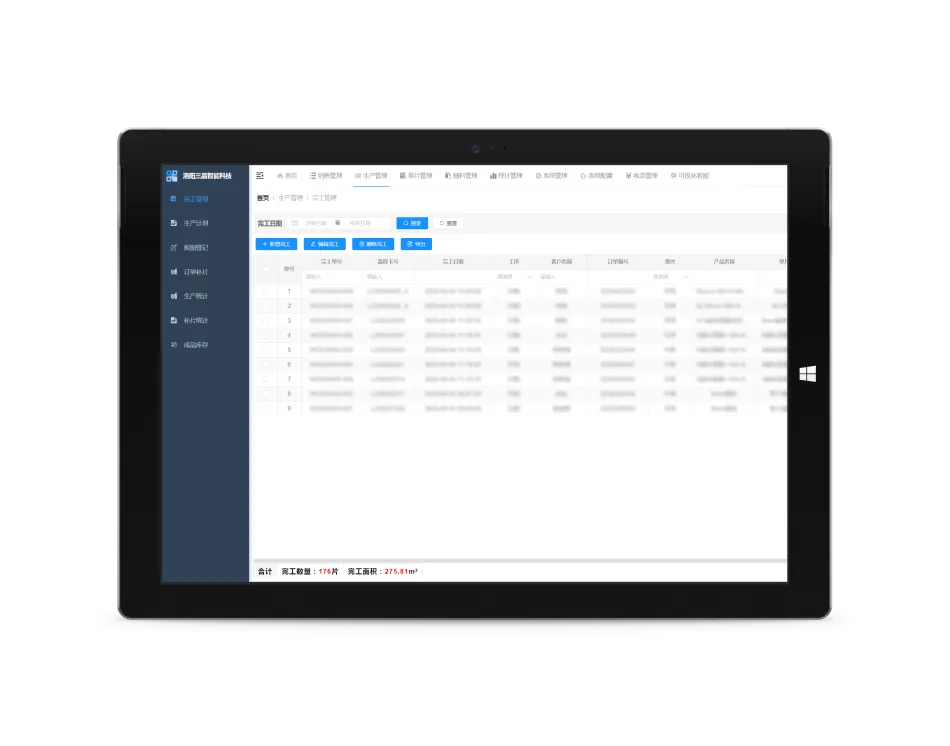

The system adopts a graphical navigation interface, and the client can quickly complete operations such as order receiving, production scheduling, delivery, and payment collection in daily trade management without installation.

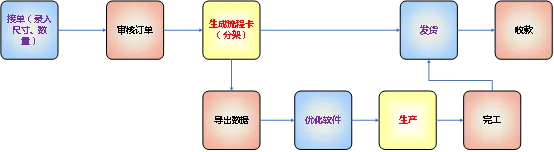

Orders

The order taker enters or imports information such as size, quantity, product and processing requirements into the system.

(1) Order review. The order reviewer reviews the order to prevent errors due to human factors during the entry process. After the review is completed, the sales order can be printed/exported and submitted to the customer for confirmation.

(2) Subracks. According to the customer, product type, processing technology and other factors, the process card (sub-rack) is divided. After the sub-rack is completed, the data can be exported to the optimization typesetting software for typesetting optimization, and the process card is printed to enter the production process.

(3) Shipping. Print the invoice, including delivery details, amount and other information.

(4) Collection. Add, edit, and review the details of each payment.

(5) Completion (by hand). Enter the completion status of each production process according to the process card (optional).

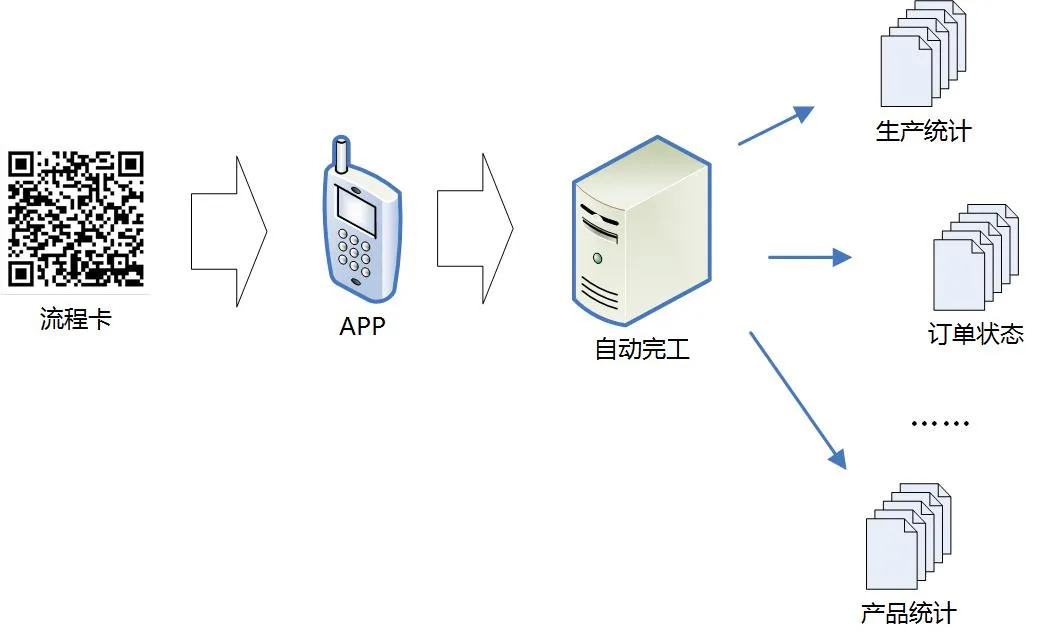

2. Production management

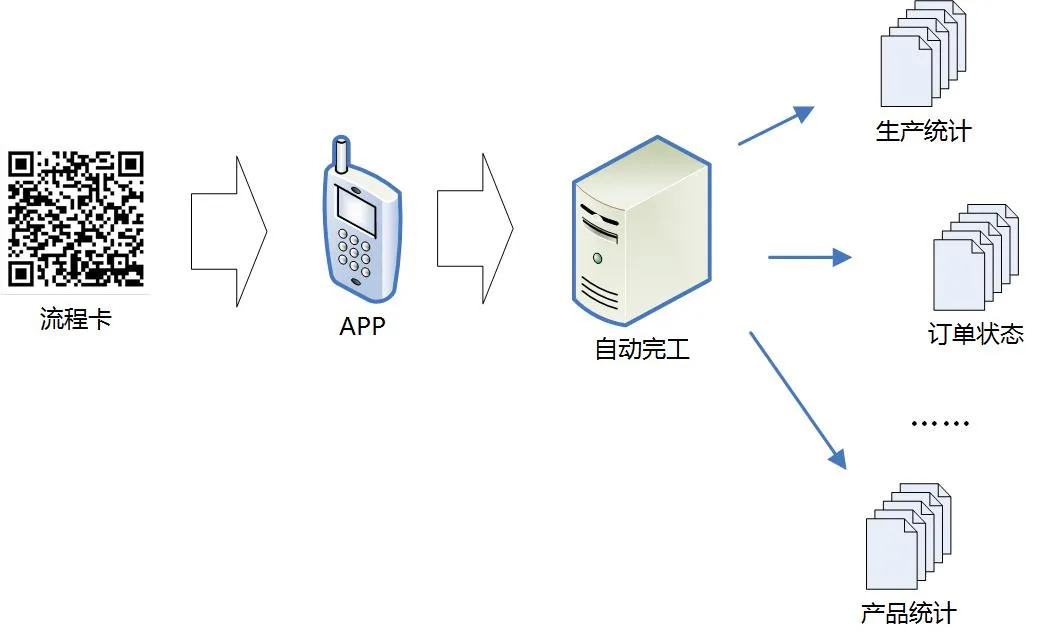

With the self-developed mobile application (APP), it can replace the manual completion operation. After the production personnel complete the production, they can use smart devices such as mobile phones to scan the QR code on the process card to automatically complete the completion operation.

3. Statistics management

The system is equipped with a variety of convenient and practical statistical functions, which can help managers understand the status of orders, production, delivery, collection, customers and inventory in real time, and provide data support for subsequent decision-making.

(1) Order statistics. Display the order volume, review volume, shelf quantity, etc. in chart form.

(2) Order statistics. Customer order status (area, amount) in chart form.

(3) Progress statistics. Take order/customer as the dimension to count the completion status of the process.

(4) Production statistics. Display the completion data and reported loss quantity of each process in chart form.

(5) Shipping statistics. Display the delivery area and delivery amount in chart form.

(6) Collection statistics. A graph showing the amount collected each day over time.

(7) Product statistics. Display the quantity and area of various products over a period of time in chart form.

(8) Type statistics. Graphically displays the number and area of monolithic types over a period of time.

(9) Inventory statistics. Display raw film/excipient inventory status in chart form.

(10) Report. Customize production weekly, monthly, annual reports, etc. according to user needs.