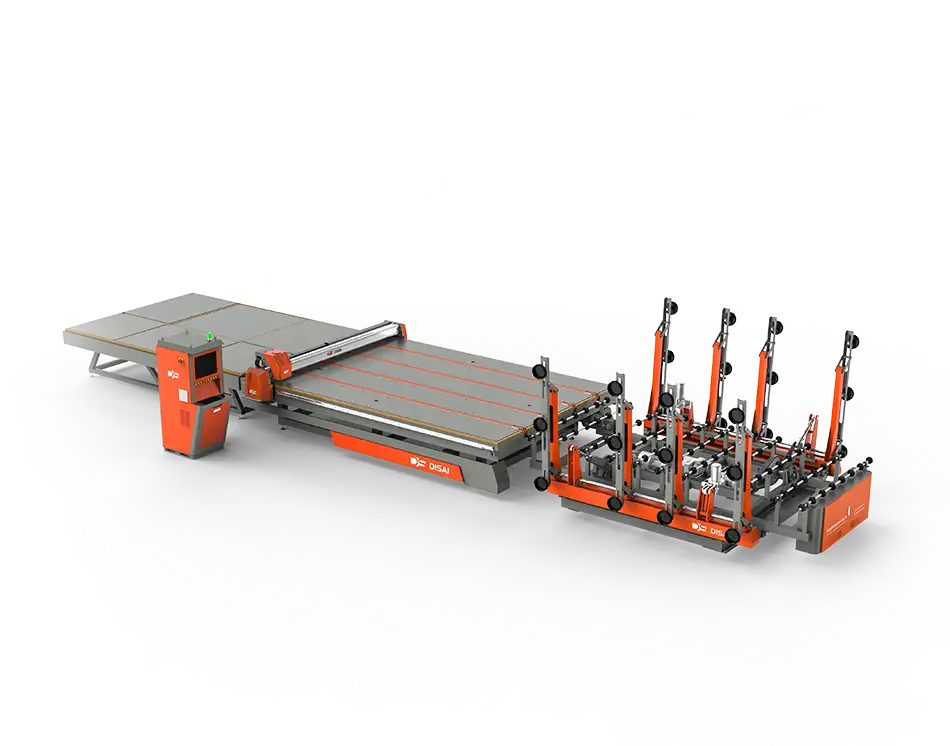

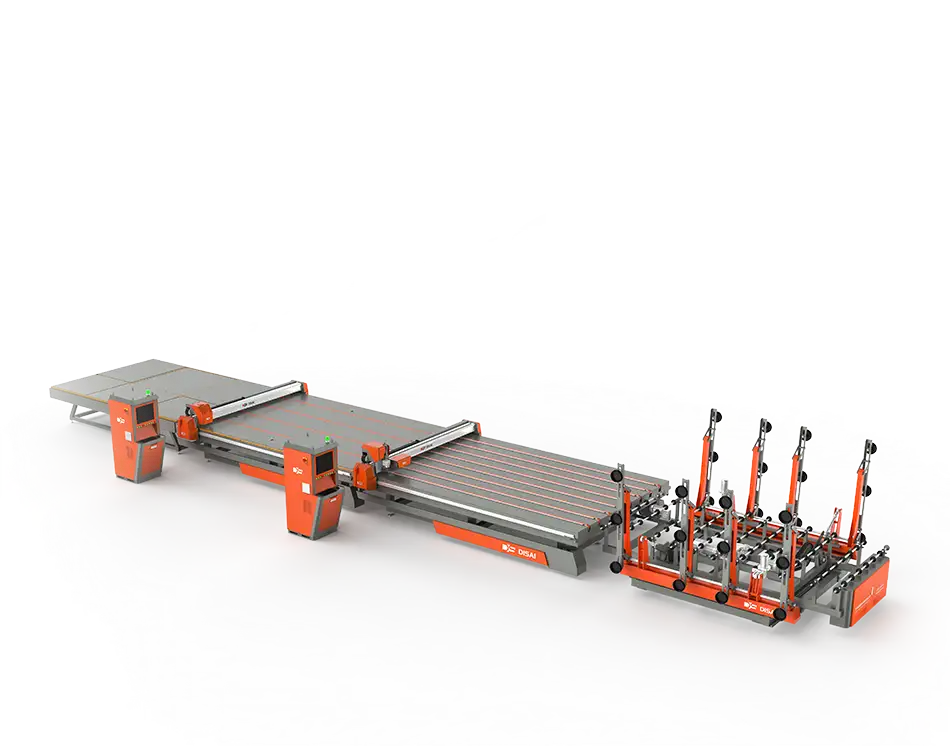

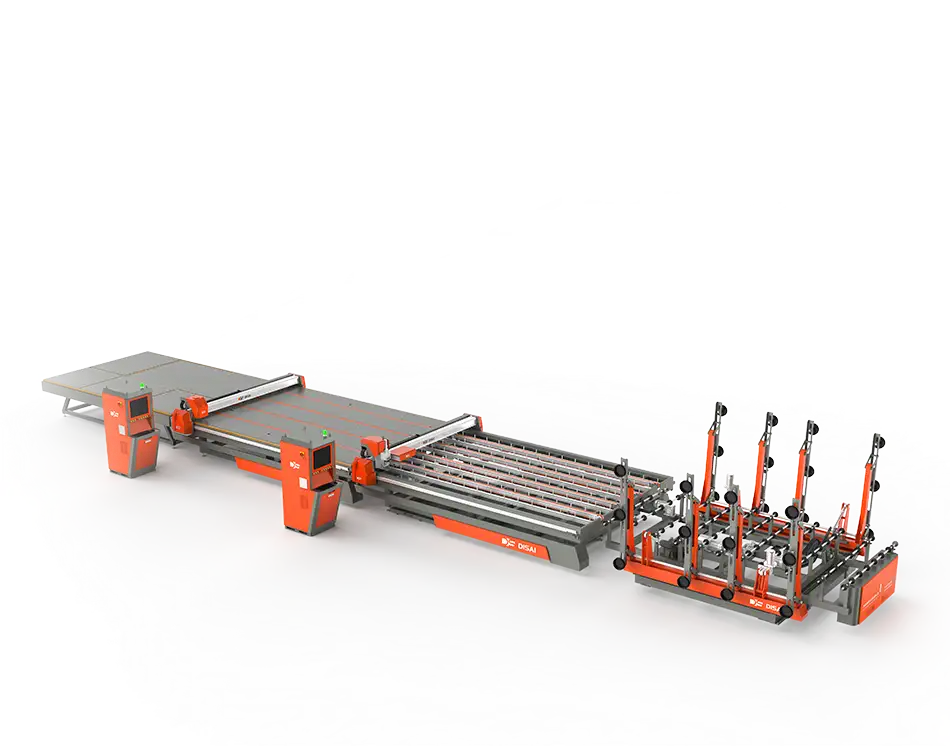

Automatic Glass Cutting Line

Automatic Glass Cutting Line(with laser marking)

Automatic Glass Cutting Line(with laser drilling)

Integrated Glass Cutting Table(Automatic Loading)

Integrated Glass Cutting Table(Manual Loading)

Tilting Glass Cutting Table

Automatic Glass Cutting Machine

Automatic Laser Marking Machine(Single Laser)

Automatic Laser Marking Machine(Double Laser)

1

1

Optimization arrangement

2

2

Library with various of common shaped graphics

3

3

Collection and processing of special shaped outlines

4

4

Laser-positioning glass cutting

5

5

Intelligent printing and labeling

6

6

Intelligent loading

Outline Collection and Processing

Intelligent Integration Module of Labeling &Printing

Automatic Glass Loading

With the module of laser scanning, outine date of all kinds of flat and shaped glass can be automatically collected and processed by its professional software.

1、To avoid intricacy and inefficiency of manual collection, and reducing measure errors.

2、With professional graphic processing software,original shape of the glass can be effectively and accurately restored and easily modified.

3、With unification technologies of collection, processing & cutting, the working accuracy can be guaranteed by the system. What' s more, the error problem resulting from incompatibility of different tools can be solved.

It is disperse, time-consuming, material-cost and error-prone for traditional manual labeling and printing. However, our itelligent module can solve all the problems caused by the traditional method, and realize the real intelligent management of printing and labeling.

1、With integration processing, no special layout and design would be required for labeling.

2、With itelligent printing control, it is labour-saving and material-saving without manual layout for printing.

3、The automatic process of labeling & printing is safe, effective and precise, which avoids the dangers or mistakes caused by manual labeling.

DISAI DS-LT series full automatic loading tables,adopt Siemens PLC controller, 7 inches colourful screen, operated by touch-screen, whose interface is changeable between Chinese and English by one button. It is very lively and simple to operate and the loading quantity can be set freely. With a special signal monitor interface, it is very convenient to check and control step work.

The process of loading is smooth and compact,time-saving and safe. And supplied with function buttons, the process can be paused and stopped by the operator in any time when necessary.

The cost of a glass cutting machine can vary widely based on several factors, including the type of machine, its specifications, capabilities, and the manufactu......

Operating an automatic glass cutting machine requires careful attention to safety and precision. Here's a general step-by-step tutorial on how to operate an aut......

A glass cutting machine is a specialized tool used to cut glass sheets or panels into desired shapes and sizes. These machines are commonly used in industries r......